3 Important Considerations to Make When Choosing the Right Portable Metal Tester for Yo

Plant and machinery should improve your bottom line by streamlining processes and increasing efficiency. A portable metal tester is often an investment well worth making for all sizes of construction or manufacturing firm.

Metal testing is typically used to check the composition of unknown alloys and metals. There are two main processes used to test metals: one is destructive and the other nondestructive. Metal testing is also used to determine the properties of alloys that have just been forged and can be part of an established manufacturing process.

Metal testing is incredibly important in the construction and manufacturing sectors. Ensuring the correct composition for steel joists or scaffolding before being deployed on-site not only saves money but also improves health and safety. Newly forged metals can also vary slightly in composition and having testing capabilities without the need to send samples to labs can improve consistency in manufacturing and help with quality control.

Metal testing machines are linked to extensive databases that contain information about numerous chemical properties in an alloy material. The two testing processes involved are as follows:

- Destructive: in the process of determining the exact composition of a material, it is destroyed in the purpose and cannot be used again

- Nondestructive: this type of metal testing is generally used in construction and manufacturing as it tests composition while allowing for it to be used again

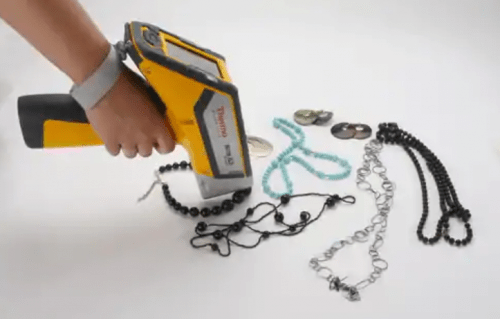

About Portable Metal Testers

Mobile or portable metal testers have been used for around 30 years to carry out metal analysis while on-site. There are three things to consider when choosing a machine, including the following:

- The most obvious advantage of a portable metal tester is its mobility. Many users require a flexible metal testing unit for use in several places on one large site, making this a practical option. Having a portable metal testing unit means that there is no need to take extensive material samples and send them away for analysis. This improves on-site efficiency and also reduces costs.

- It is important to know what kind of materials you are most likely to need to test on a regular basis as machines may vary as to what they can analyze. That said modern-day portable metal testers are much more comprehensive than in the past, with many analytical functions available in much smaller machine sizes.

- Portable metal testers are very robust, with a rugged design that is intended to be extremely durable over the long term. The extent to which your operation requires metal testing will determine the type of design you choose although they are generally relatively lightweight while being tough enough to last. Durability is an important consideration as metal testing machines have to endure significant handling on-site.

Ideally, a portable metal tester should provide as much function as lab-testing ordinarily would. Detecting complex alloys or nitrogen in duplex steels is one of the important functions of a portable machine on a construction site and they have been shown to significantly reduce costs.

Plant and machinery should improve your bottom line by streamlining processes and increasing efficiency. A portable metal tester is often an investment well worth making for all sizes of construction or manufacturing firm.

To join us on Facebook Click Here and Subscribe to UdaipurTimes Broadcast channels on GoogleNews | Telegram | Signal