Handle with Care: Prevent Injuries with Proper Lifting Techniques

Contributed by: Dr. Suman Singh (Emeritus Professor) & Bipasha Bhomick (Scholar)

Have you ever lifted a heavy box, moved furniture, or carried items at work? These activities are part of manual material handling. It involves moving or supporting a load by human effort. This includes activities such as lifting, carrying, pushing, pulling, lowering, and stacking objects. MMH tasks are common in various workplaces, including homes, agriculture work, warehouses, construction sites, factories, and offices. Proper MMH techniques are essential to prevent injuries, particularly to the back and musculoskeletal system, and to promote efficiency and safety in the workplace. Let's explore the basics of manual material handling, its risks, and how to do it safely.

What is Manual Material Handling?

Key aspects of MMH include:

- Lifting: Raising an object from a lower level to a higher level.

- Carrying: Moving an object by holding it while walking.

- Pushing and Pulling: Moving an object by applying force to move it away or towards the body.

- Lowering: Bringing an object from a higher level to a lower level.

- Stacking: Placing one object on top of another.

Effective MMH practices involve assessing the load, using proper body mechanics, seeking assistance for heavy or awkward loads, and employing tools or equipment such as hand trucks, conveyors, and lifts to reduce the physical strain on workers.

Manual material handling (MMH) refers to the process of moving items without the help of machines. It’s common in many jobs, from Household work to farm work to construction and manufacturing to retail and healthcare. Tasks can include lifting bags, boxes, stacking shelves, and moving equipment. While these tasks are necessary, they can be physically demanding and, if not done correctly, can lead to serious injuries.

Risks and Hazards

One of the biggest risks of manual material handling is musculoskeletal disorders (MSDs). These are injuries to the muscles, nerves, tendons, joints, cartilage, or spinal discs. Common MSDs related to MMH include back injuries, shoulder strains, and repetitive strain injuries. These injuries can result from lifting heavy loads, awkward postures, repetitive movements, or sudden force.

Common Causes of Injuries

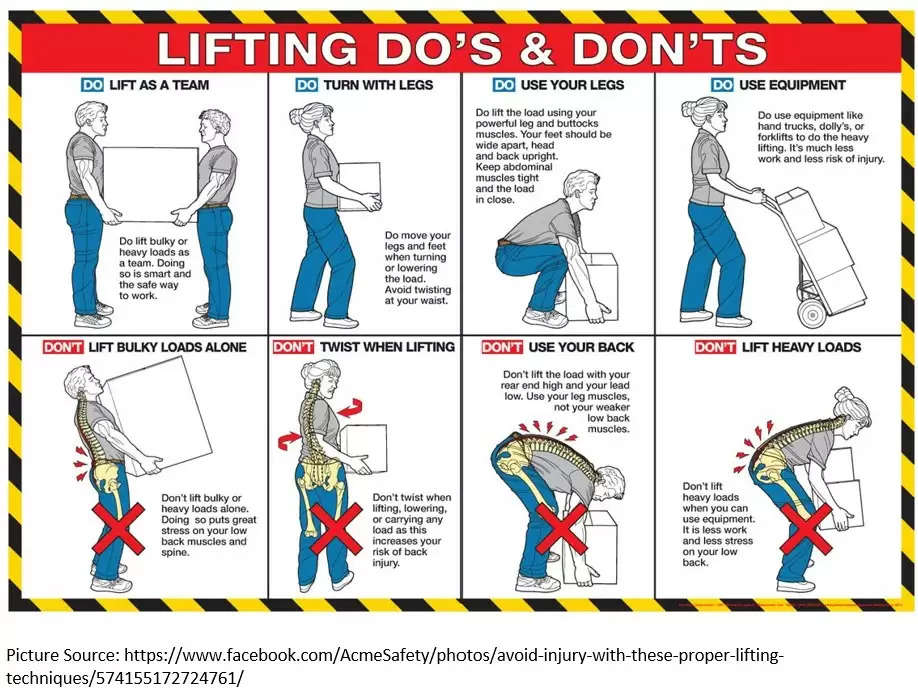

Several factors contribute to injuries during manual material handling. Poor lifting techniques, such as bending at the waist instead of the knees, can put excessive strain on your back. Carrying loads that are too heavy or awkward to handle increases the risk of dropping them or straining muscles. Repetitive tasks can lead to overuse injuries, and improper grip or handling can cause items to slip, leading to accidents.

Safe Manual Material Handling Practices

- Plan Ahead: Before lifting or moving an item, plan your route and ensure there are no obstacles in the way. This helps you avoid sudden movements and maintain balance.

- Use Proper Lifting Techniques: Always bend your knees, not your waist, when lifting heavy objects. Keep the load close to your body and use your leg muscles to lift, which are stronger than your back muscles. Pushing power is greater than pulling, so choose to push rather than pull. Pulling and pushing power greater in vertical plane and lowest in horizontal plane.

- Keep a Good Posture: Maintain a straight back and avoid twisting while lifting. If you need to turn, move your feet instead of twisting your torso.

- Lift and Lower Loads at Proper Heights: Lift and lower/release loads preferably not below knee height. Don’t lift and release load above shoulder height.

- Use Equipment: When possible, use tools like dollies, hand trucks, or forklifts to move heavy items. This reduces the physical strain on your body.

- Work in Teams: For particularly heavy or bulky items, ask for help. Team lifting can distribute the weight more evenly and reduce the risk of injury.

- Take Breaks: Don’t overexert yourself. Take regular breaks to rest your muscles and avoid fatigue, which can lead to poor handling techniques and accidents.

| “Manual material handling is also very important in agriculture work. In agriculture, safe manual material handling is the backbone of a healthy workforce, ensuring that farmers and laborers can sustain their vital work without compromising their physical well-being through proper techniques and ergonomic practices."- Dr Hemu Rathore, HOD RMCS Dept, CCAs, MPUAT, Udaipur. |

Importance of Training and Ergonomics

Training is crucial for safe manual material handling. Workers should be educated on proper lifting techniques, the use of handling equipment, and the importance of ergonomics. Ergonomics involves designing tasks and workspaces to fit the worker’s needs, reducing the risk of injury. For example, adjusting the height of shelves to avoid excessive bending or reaching can make a big difference.

Since, manual material handling is a common part of many jobs but comes with risks if not done correctly. Understanding the hazards and following safe handling practices can prevent injuries and ensure a safer work environment. Remember to use proper lifting techniques, plan your tasks, and use available equipment. By taking these steps, you can protect yourself and your co-workers from the dangers of manual material handling. Stay safe and lift smart!To join us on Facebook Click Here and Subscribe to UdaipurTimes Broadcast channels on GoogleNews | Telegram | Signal